Materials scientists have pursued the question of why vertically aligned carbon nanotube forests show much lower modulus values than expected. Now researchers from Georgia Tech have found that the nanotubes they fabricate contain kinks that dramatically diminish modulus value. In other words, the nanotubes are not straight; therefore, they are not stiff.

The government-funded research was recently published in Carbon, and the first sentence of the Abstract reads, “Waviness is invariably present in vertically-aligned Carbon Nanotubes (CNTs) regardless of how controlled the fabrication process is.” As described in the journal article, and in a reprinted news article at ScienceDaily.com, the inescapably wavy nanotube forests afford possible heat management applications:

Carbon nanotubes provide many attractive properties, including high electrical and thermal conductivity, and high strength. Individual carbon nanotubes have a modulus ranging from 100 gigapascals to 1.5 terapascals. Arrays of vertically-aligned carbon nanotubes with a low density would be expected to a have an effective modulus of at least five to 150 gigapascals, Sitaraman said, but scientists have typically measured values that are four orders or magnitude less — between one and 10 megapascals.

…

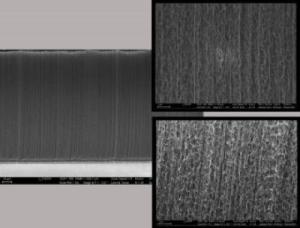

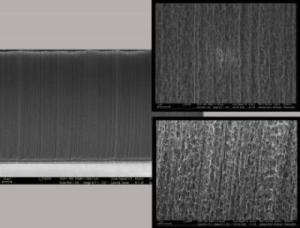

To look for potential explanations, the researchers examined the carbon nanotubes using scanning electron microscopes located in Georgia Tech’s Institute for Electronics and Nanotechnology facilities. At magnification of 10,000 times, they saw the waviness in sections of the nanotubes.“We found very tiny kinks in the carbon nanotubes,” said Sitaraman. “Although they appeared to be perfectly straight, there was waviness in them. The more waviness we saw, the lower their stiffness was.”

…

Though the loss of modulus might seem like a problem, it actually may be helpful in thermal management applications, Sitaraman said. The compliance of the nanotubes allows them to connect to a silicon integrated circuit on one side, and be bonded to a copper heat spreader on the other side. The flexibility of the nanotubes allows them to move as the top and bottom structures expand and contract at different rates due to temperature changes.“The beauty of the carbon nanotubes is that they act like springs between the silicon chip and the copper heat spreader,” said Sitaraman. “They can conduct lots of heat because of good thermal properties, and at the same time, they are supple and compliant.”

…

Carbon nanotubes have extraordinarily high thermal conductivity, as much as ten times that of copper, making them ideal for drawing heat away from the chips.“The demand for heat removal from chips is continuing to increase,” said Ginga. “Industry has been looking for new materials and new techniques to add to their toolbox for heat transfer. Different approaches will be needed for different devices, and this provides the industry with a new way to address the challenge.”

-Posted by Stephanie C