Nanofabrication Study on Suspended Carbon Nanotube Structures

Seung-Beck Lee*, a, K. B. K.Teob, M. Chhowallab, D. G. Haskoa, G. Amaratungab, W. I. Milneb, and H. Ahmeda

aCavendish Laboratory, University of Cambridge,

Cambridge, CB3 0HE, UK

bEngineering Department, University of Cambridge

Cambridge, CB2 1PZ, UK

This is an abstract

for a presentation given at the

10th

Foresight Conference on Molecular Nanotechnology

The superior mechanical properties of carbon nanotubes make them ideal candidates for Nano-Electrical Mechanical System (NEMS) applications [1,2,3,4]. Most of the proposed NEMS applications of carbon nanotubes, such as nano-tweezers [2], nano-bearing [3], and nano-actuators [4], require the nanotubes to be suspended above the supporting substrate if it is to be integrated onto a chip. Therefore a reliable method of suspending carbon nanotubes must be found. More importantly, for electrical access and control of the suspended carbon nanotube structures, a method of placing individual control electrodes with nanoscale precision is required.

We present a study on the nanofabrication of suspended carbon nanotube structures and also on the use of suspended nanotube structures for self-aligned processes. To suspend carbon nanotubes, a sacrificial layer and etching method is used. First, we use thermally oxidised Si as the substrate on which an Al sacrificial layer is deposited. Then the nanotubes are dispersed in a solution of dichlorobenzene and sonicated before being spin-coated onto the sample surface. After mapping the positions of the nanotubes, electron beam lithography is used to define the electrode pattern and the sacrificial layer for that pattern is chemically removed. Finally, metal electrodes are deposited and after lift-off, the remaining Al is removed to produce a suspended carbon nanotube structure.

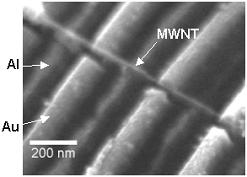

Figure 1 illustrates how suspended carbon nanotube can be utilised as self-aligned evaporation masks for electrode deposition. A suspended multi-wall carbon nanotube (diameter ~ 10 nm) was used as an evaporation mask for the deposition of Au electrodes perpendicular to the nanotube orientation. The nanotube is suspended ~ 50 nm above the substrate. The array of Al wires are the under-etched sacrificial layer which is continuous. The Au deposited on the nanotube has been lifted-off, while it remains on the SiO2 surface. This may be due to the difference in binding energies between the interface components [5]. The Au wires now contains a nano-gap and have formed self-aligned split gate structures nanometers from the suspended nanotube. With further developments, the fabrication technique should prove useful for NEMS application using carbon nanotubes.

Figure 1

References:

- E. W. Wong, P. E. Sheehan and C. M. Lieber, Science, 277 (1997) 1971.

- P. Kim and C. M. Lieber, Science, 286 (1999) 2148.

- J Cumings and A. Zettl, Science, 289 (2000) 602.

- R. H. Baughman, C. Cui, A. A. Zakhidov, Z. Iqbal, J. N. Barisci, G. M. Spinks, G. G. Wallace, A. Mazzoldi, D. De Rossi, A. G. Rinzler, O. Jaschinski, S. Roth and M. Kertesz, Science, 284 (1999) 1340.

- Y. Zheng and H Dai, Appl. Phys. Lett. 77 (2000) 3015.

*Corresponding Address:

Seung-Beck Lee

Cavendish Laboratory, University of Cambridge,

Madingley Road, Cambridge, CB3 0HE, UK

Phone: +44-1223-337555 Fax: +44-1223-337706

Email: [email protected]

Web: http://www.cus.cam.ac.uk/~sbl22

|