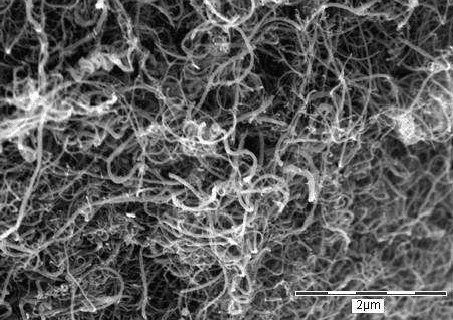

Bayer (the same company that makes the aspirin) is now beginning to manufacture multi-walled carbon nanotubes in industrial quantities. The pilot plant will produce 200 tons per year, and the market is expected to grow at 25% per year.

The MWCNTs are for materials use, meaning mostly fiber-reinforced composites, e.g. airplanes, tennis racquets, arrows,

and the like. The major advantages over conventional polymers / fibers is that the CNTs are stronger and conductive (both electrically and thermally) — producing a plastic that is more like metal in many ways, but still much lighter. The conductivity is supposed to be comparable to copper, i.e. good enough to use as wiring in many applications. Looking at the data for CNTs as a polymer additive, the major effect on mechanical properties was to make them less stretchy (and about 10% stronger), while having a major effect on conductivity properties. Nobody has yet, as far as I know, managed to figure out how to make a composite that has the really high tensile strength possibilities of the raw nanotubes. Alternatively, CNTs in light metal matrices such as aluminum or magnesium seems to have significant possibilities. Time will tell — but there’s still a major advance to be made.

The individual CNTs in the mix are on average 8 or so walls, 15 nm diameter, and over a micron long (i.e. an aspect ratio of at least 60 and probably in the hundreds).