Recently highlighted in a C&EN article titled Simple Process Creates Near-Perfect Mirrors Out of a Metamaterial, researchers out of Vanderbilt University developed a method to self-assemble silicon nanostructures to achieve highly (Bragg-like) reflective mirrors which capitalize on nanoscale properties not present in bulk structures. The self-assembly method is far simpler than previous, conventional electron beam lithography approaches.

…Metamaterials are engineered to have properties, typically derived from nanoscale patterning, that do not occur in the bulk material. They made their reflector by patterning a silicon wafer’s surface with an array of silicon cylinders a few hundred nanometers in diameter. Each of the cylinders acted like a tiny resonator for particular light frequencies—analogous to the way certain sound frequencies will make a tuning fork hum. By adjusting the size of the cylinders, Valentine could control how well they reflected light of a given frequency. This mirror reflected more than 99% of light at the peak wavelength.

Although the work showed that metamaterial mirrors could be effective, the method for making them was far from practical: The researchers painstakingly created the arrays using electron-beam lithography, which is difficult to scale up. So Valentine and his team adopted a simpler method to make bigger, near-perfect reflectors.

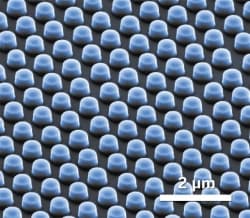

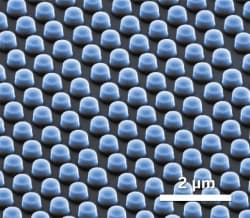

They started with off-the-shelf polystyrene beads 820 nm across and dropped them into a film of water. Driven by electrostatic forces, the beads self-assembled into a monolayer on the water’s surface with a repeated hexagonal pattern. Valentine’s group then drained the water, lowering the bead layer onto a submerged silicon wafer, and used a plasma etching process to shrink the beads to 560 nm. Finally, they used the bead layer as a lithographic mask to pattern the underlying silicon. The resulting 2-cm2 arrays were covered in silicon cylinders, each 335 nm tall and 480 nm across the top.The arrays reflect 99.7% of incident infrared light at 1,530 nm. Valentine is now working on making larger area reflectors by patterning with silicon nanospheres.

“This is a phenomenal result, especially for something made by self-assembly,” says Michael B. Sinclair, who develops metamaterials at Sandia National Laboratories. Bragg reflectors are an established technology that will be difficult to compete with anytime soon, he says, but the work is “an impressive step forward for making large-area metamaterials.”

-Posted by Stephanie C