Foresight’s recent Workshop on Directed/Programmable Matter for Energy focused on the potential of atomically precise materials for energy production, transport, and efficient use. A hat tip to Kurzweil Accelerating Intelligence for describing how scientists from Tohoku University in Japan had combined carbon nanotube field emitters with a solution of indium oxide and tin oxide to produce a very efficient planar light source. From an AIP Publishing news release by Zhengzheng Zhang “Beyond LEDs: Brighter, New Energy-Saving Flat Panel Lights Based on Carbon Nanotubes“:

Even as the 2014 Nobel Prize in Physics has enshrined light emitting diodes (LEDs) as the single most significant and disruptive energy-efficient lighting solution of today, scientists around the world continue unabated to search for the even-better-bulbs of tomorrow.

Enter carbon electronics.

Electronics based on carbon, especially carbon nanotubes (CNTs), are emerging as successors to silicon for making semiconductor materials, And they may enable a new generation of brighter, low-power, low-cost lighting devices that could challenge the dominance of light-emitting diodes (LEDs) in the future and help meet society’s ever-escalating demand for greener bulbs.

Scientists from Tohoku University in Japan have developed a new type of energy-efficient flat light source based on carbon nanotubes with very low power consumption of around 0.1 Watt for every hour’s operation — about a hundred times lower than that of an LED.

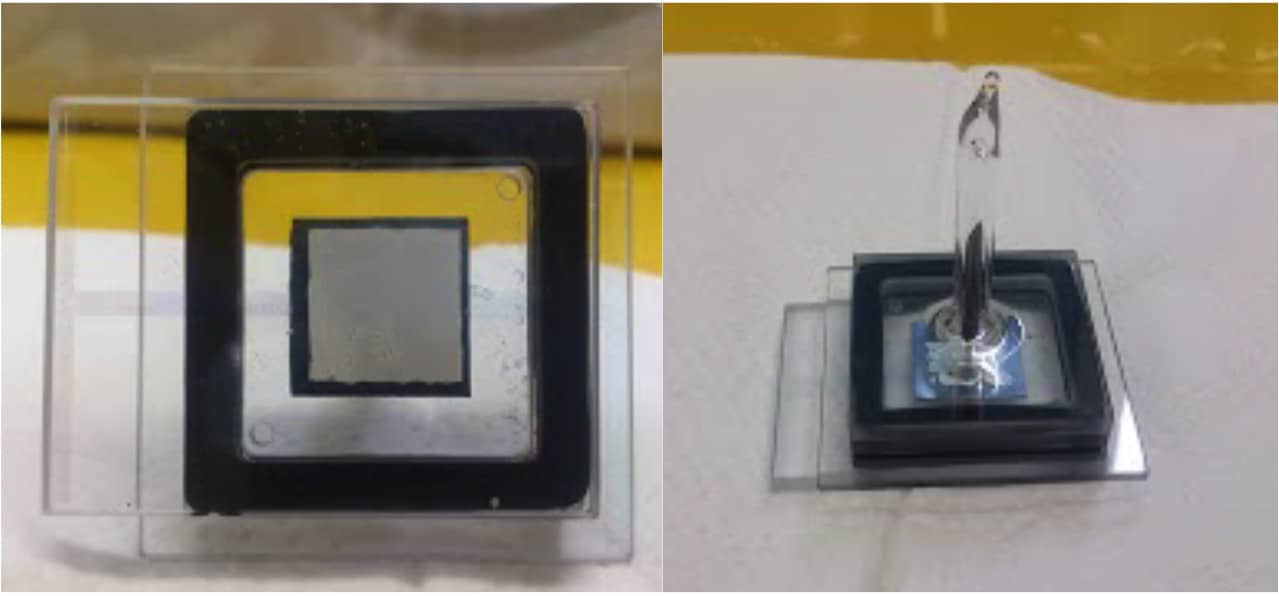

In the journal Review of Scientific Instruments [abstract], from AIP Publishing, the researchers detail the fabrication and optimization of the device, which is based on a phosphor screen and single-walled carbon nanotubes as electrodes in a diode structure. You can think of it as a field of tungsten filaments shrunk to microscopic proportions.

They assembled the device from a mixture liquid containing highly crystalline single-walled carbon nanotubes dispersed in an organic solvent mixed with a soap-like chemical known as a surfactant. Then, they “painted” the mixture onto the positive electrode or cathode, and scratched the surface with sandpaper to form a light panel capable of producing a large, stable and homogenous emission current with low energy consumption.

“Our simple ‘diode’ panel could obtain high brightness efficiency of 60 Lumen per Watt, which holds excellent potential for a lighting device with low power consumption,” said Norihiro Shimoi, the lead researcher and an associate professor of environmental studies at the Tohoku University. …

This work demonstrates that it is not necessary to develop a complete atomically precise manufacturing system to obtain many of the benefits provided by atomically precise materials; in this case the product was fabricated by painting a liquid containing highly crystalline single-walled carbon nanotubes onto a cathode. The critical factor in achieving high energy efficiency was the atomically precise nature of the carbon nanotubes:

Highly crystalline single-walled carbon nanotubes (HCSWCNT) have nearly zero defects in the carbon network on the surface, Shimoi explained. “The resistance of cathode electrode with highly crystalline single-walled carbon nanotube is very low. Thus, the new flat-panel device has smaller energy loss compared with other current lighting devices, which can be used to make energy-efficient cathodes that [function] with low power consumption.”

The remainder of the manufacturing process is a stable, low-cost method to fabricate uniformly thin films of large area.

—James Lewis, PhD