As we have frequently pointed out (for example), RNA has several properties different from those of its close cousin DNA that provide unique opportunities for RNA nanotechnology. One disadvantage of RNA nanostructures is that they are relatively easy to dissociate. RNA nanotechnology pioneer Peixuan Guo has now used rational design to further improve the stability of the unusually stable pRNA-3WJ3 motif to create new RNA triangular nanoparticles. A hat tip to Nanowerk for reprinting this University of Kentucky news release “RNA shows potential as boiling-resistant anionic polymer material for nanoarchitectures“:

A team of nanotechnology researchers at the University of Kentucky has discovered new methods to build heat resistant nanostructures and arrays using RNA.

The research, led by Peixuan Guo, professor and William Farish Endowed Chair in Nanobiotechnology at the UK College of Pharmacy and Markey Cancer Center, is reported in an article titled “RNA as a Boiling-Resistant Anionic Polymer Material To Build Robust Structures with Defined Shape and Stoichiometry,” coauthored by Emil F. Khisamutdinov and Daniel L. Jasinski.

The article, [appearing in] the journal ACS Nano, published by the American Chemical Society (ACS), was selected as an ACS “Editors’ Choice” and … is available for free download as a PDF through open access at http://dx.doi.org/10.1021/nn5006254.

Chemical polymers have seen extensive use in a variety of industries including clothing, piping, plastics, containers, bottles, cookware, tools and medical materials for drug delivery and tissue engineer materials because of their high stability and ability to hold their global shape and size. However, on the microscopic scale, these polymers form into random micro-structures, making their size and shape difficult to control.

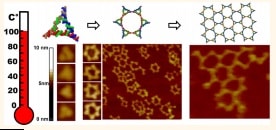

The Guo lab reports that RNA (ribonucleic acid) can be used as an anionic polymer material to build nanostructures with controllable shape and defined structure. The researchers have fabricated a new RNA triangle structure that utilizes RNA’s intrinsic control over shape and size on the nano scale, while demonstrating strong stability.

Previously, RNA was seen as structurally fragile and easily dissociable at a range of temperatures from 35-70 degrees Celsius, making its application feasibility in an industrial setting very limited. Using the special RNA motif discovered in Guo’s lab and a new methodology, the researchers demonstrated that they can build RNA nanostructures and patterned arrays that are resistant to 100 degrees Celsius, the boiling temperature of water.

The new RNA triangular nanoarchitechtures can be used to form arrays with a controllable repeat number of the scaffold, resembling monomer units in a polymerization reaction. Thus, the Guo lab was able to produce a honeycomb RNA structure with the new RNAs, allowing for the production of RNA sheets.

Experts say this breakthrough pushes the field of RNA nanotechnology forward, positioning RNA to be a new, unique type of polymer with advantages over conventional chemical polymers.

“This research shows great potential for building stable RNA nanoparticles with properties that could be more easily controlled than standard polymers,” said Jessica Tucker, National Institute of Biomedical Imaging and Bioengineering program director for drug and gene delivery systems and devices. “The more control we have over the nanoparticles, the better we can tailor them for use in therapeutics for diseases ranging from cancer to diabetes.”

The more complex molecular recognition code of RNA compared to that of DNA gives RNA nanotechnology unique advantages as a path toward complex molecular machine systems, as we have pointed out previously. Added to these advantages, the new unusually robust 12-nm triangular building blocks reported in this work, which have the ability to carry multiple functional RNA devices, and also to assemble into larger honeycomb-like scaffolds with 35-nm central cavities, may also be able to partially mimic or to complement some uses of the origami and brick structures made possible by DNA nanotechnology. The most obvious and probably the most near-term application of RNA nanotechnology will be in nanomedicine for drug delivery, diagnosis, and tissue engineering. Other applications could lead to more complex molecular machine systems that will make possible productive nanosystems that will in turn make possible what has been termed “molecular manufacturing” or “atomically precise manufacturing”.

—James Lewis, PhD