Scientists, engineers, and enthusiasts can help bolster the understanding of and enthusiasm for nanotechnology in local communities with a little help from National Chemistry Week (October 21st-27th) and other user-friendly, volunteer programs.

Scientists, engineers, and enthusiasts can help bolster the understanding of and enthusiasm for nanotechnology in local communities with a little help from National Chemistry Week (October 21st-27th) and other user-friendly, volunteer programs.

Large molecular cages constructed from metal-organic frameworks have set a record for the greatest surface area in the least mass.

Metal-organic frameworks (MOFs) are back in the news again. A few months ago we cited the use of MOFs by Canadian chemists to self-assemble a molecular wheel on an axis in a solid material. More recently chemists at Northwestern University have used MOFs to set a world record for surface area. From “A world record for highest-surface-area materials“:

Northwestern University researchers have broken a world record by creating two new synthetic materials with the greatest amount of surface areas reported to date.

Named NU-109 and NU-110, the materials belong to a class of crystalline nanostructure known as metal-organic frameworks (MOFs) that are promising vessels for natural-gas and hydrogen storage for vehicles, and for catalysts, chemical sensing, light harvesting, drug delivery, and other uses requiring a large surface area per unit weight.

The materials’ promise lies in their vast internal surface area. If the internal surface area of one NU-110 crystal the size of a grain of salt could be unfolded, the surface area would cover a desktop. …

MOFs are composed of organic linkers held together by metal atoms, resulting in a molecular cage-like structure. The researchers believe they may be able to more than double the surface area of the materials by using less bulky linker units in the materials’ design. …

Beyond their near-term practical applications, Eric Drexler has cited MOFs as potentially useful building blocks in the molecular machine path to molecular manufacturing. Near-term applications may drive the technology development to produce more choices for molecular machine system components.

—James Lewis, PhD

Optimizing the size and charge of nanoparticles engineered from polymers delivers drugs directly to mitochondria, effectively treating cells with drugs for a variety of diseases.

A brief article reviews several types of molecular machines that chemists have built to mimic biology and provide movement for future types of nanotechnology.

A “cut and paste” method uses an atomic force microscope to assemble protein and DNA molecules to form arbitrarily complex patterns on a surface. Developing this approach to form enzymatic assembly lines could be a path toward a general purpose nanofactory.

An online course coupled with hands on training in Field Emission Scanning Electron Microscopy and Transmission Electron Microscopy given in Mountain View, California, is being offered by Foothill College and NASA-ASL (NASA-Ames).

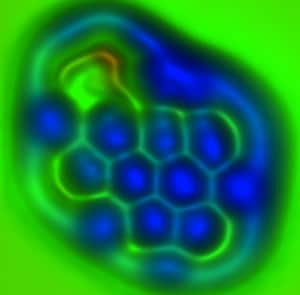

Noncontact atomic force microscopy using a tip functionalized with a single molecule provides highly precise measurement of individual chemical bond lengths and bond orders (roughly, bond strength).

Millions of organic chemicals and reactions have been incoporated into a huge computer network along with search algorithms to find new synthetic pathways. A way to find new building blocks for molecular nanotechnology?

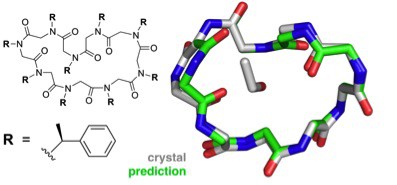

A combination of theoretical and experimental work on peptoids, synthetic analogs of proteins, points to the ability to design peptoids with desired structures and functions.

September 6, 2012. San Francisco. General admission to Design Night is $20 and student admission is $10. Admission fees include access to the exhibits, content such as a speaker, music, a hosted bar, and hands-on activities.